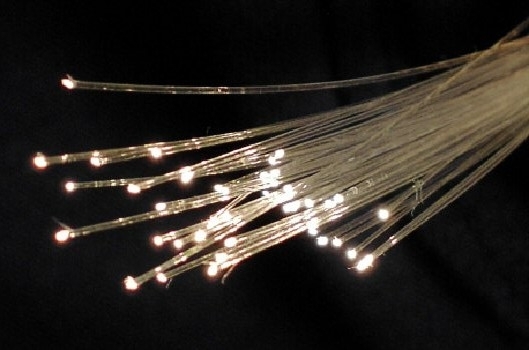

The conventional process requires costly large-scale equipment. The novel method can be executed in a single step by a device no larger than a microwave oven (image: Wikimedia Commons)

Published on 03/18/2021

By José Tadeu Arantes | Agência FAPESP – A novel process to fabricate special optical fiber that is far simpler, faster and cheaper than the conventional method has been developed by Cristiano Cordeiro, a researcher and professor at the University of Campinas’s Physics Institute (IFGW-Unicamp) in the state of São Paulo, Brazil. Cordeiro created the innovation during a research internship at the University of Adelaide in Australia, supported by a scholarship from FAPESP and by a partnership with his host, Heike Ebendorff-Heidepriem. An article signed by them and a third collaborator is published in Scientific Reports.

“The conventional process requires very large and expensive machinery and takes almost a week. Our process can be completed with bench-mounted equipment that’s at least 100 times cheaper and takes less than an hour from feedstock to end-product. It will enable many more researchers and labs to produce their own optical fiber,” Cordeiro told Agência FAPESP.

The procedure roughly resembles the extrusion method used to produce pasta: pressure is brought to bear on a ductile material so as to force it through a die, producing fiber with the appropriate inner structure. “Of course, this is all done with much more rigor and precision,” Cordeiro said.

Hundreds of millions of kilometers of optical fiber are installed worldwide, and the amount of data they transport doubles approximately every two years. They are used not only in telecommunications but also for remote sensing to monitor temperature, mechanical stress, hydrostatic pressure, or fluid flow, among many other parameters. Thanks to their strength and thinness they are effective in hostile environments and barely accessible locations.

These features help explain the importance of innovative fabrication processes. “The conventional process has several stages and requires highly complex equipment, such as a fiber drawing tower,” Cordeiro said. “First a preform is produced, a giant version of the fiber with a diameter of between 2 cm and 10 cm. This structure is heated and drawn in a highly controlled manner by the tower. Mass is conserved and diameter decreases as length increases. Our method simplifies the process at an enormously reduced cost. The device we designed carries out a single continuous process starting with polymer pellets and ending with the finished fiber.”

The procedure can be used to fabricate not only all-solid fiber, in which light is transmitted via a core with a higher refractive index but also microstructured fiber containing an array of longitudinal holes, which enhances optical properties control and brings an increase in functionality – including the opportunity to guide light with low energy loss in an air channel. To create the microstructures, the researchers used titanium dies with suitable designs.

“To simplify the fabrication of special optical fiber, we deployed equipment and techniques that are becoming more affordable and accessible thanks to the popularization of 3D printing,” Cordeiro said. “The only machine required is a compact horizontal extruder similar to the device used to produce filament for 3D printers. It’s about the size of a microwave oven and is far less costly than a draw tower. The titanium die with solid parts and holes is coupled to the extruder exit.”

Owing to the fiber’s intricate inner structure, the researchers produced the dies by additive manufacturing using appropriate 3D printers. Specialist firms can provide additive manufacturing services, so the only item of equipment need to produce the fiber is the horizontal extruder.

The article “Ultra-simplified single-step fabrication of microstructured optical fiber” by Cristiano M. B. Cordeiro, Alson K. L. Ng and Heike Ebendorff-Heidepriem can be read at: www.nature.com/articles/s41598-020-66632-3.

Source: https://agencia.fapesp.br/34071