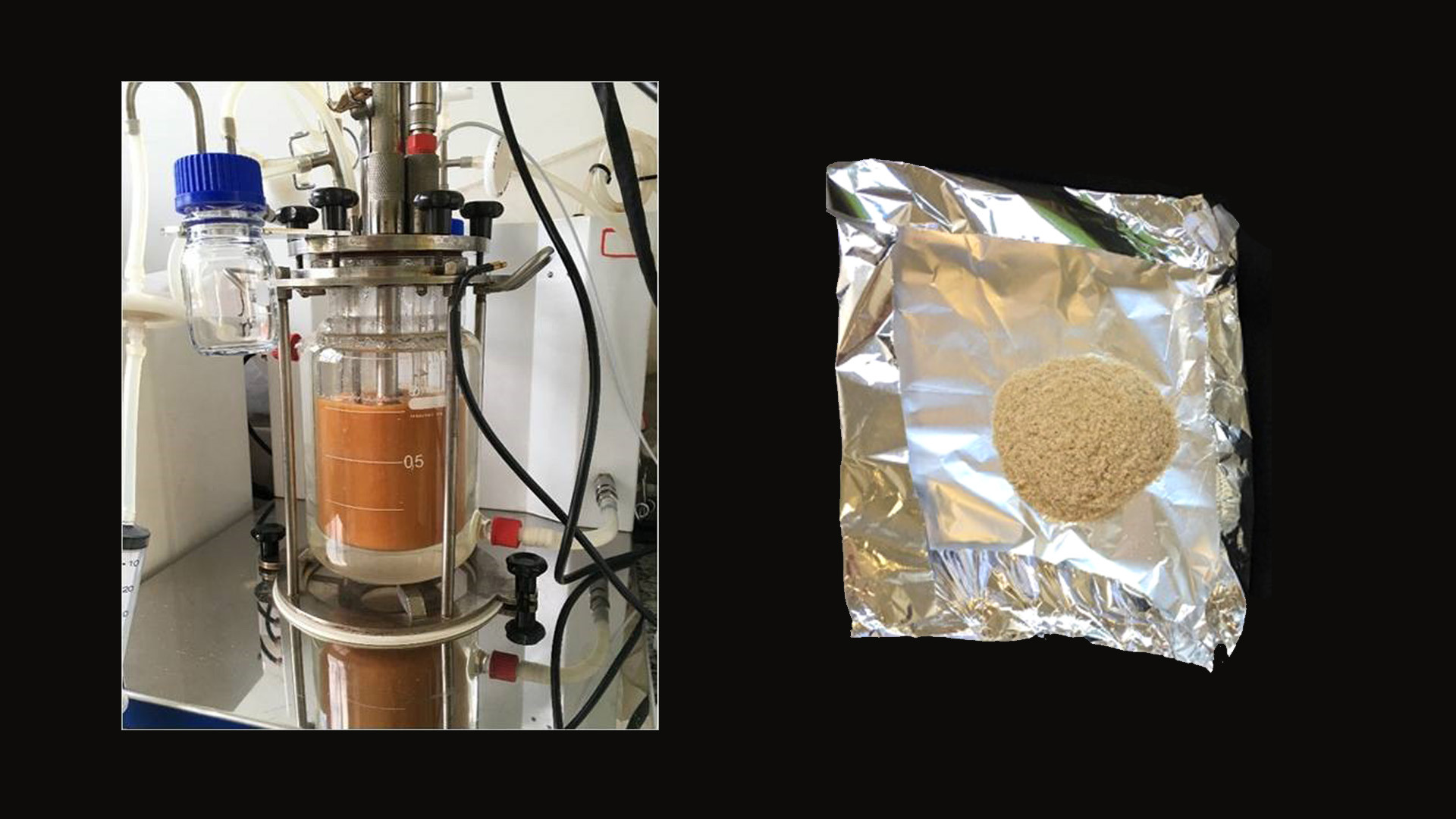

On the left, fermentation of molasses and shrimp waste by lactic acid bacteria; on the right, chitosan powder resulting from the process developed at UFSCar (photos: researchers’ collection)

Published on 03/10/2025

By José Tadeu Arantes | Agência FAPESP – Chitosan is a bioadhesive, biodegradable and potentially antimicrobial polymer with multiple applications: in agriculture, for pest control and preservation of agricultural products; in industry, for the manufacture of biodegradable coatings and packaging; in the pharmaceutical sector, for the manufacture of dressings and encapsulation of drugs.

Research carried out at the Federal University of São Carlos (UFSCar), at its campus in Araras (state of São Paulo, Brazil), has shown that chitosan can also be used as a natural antimicrobial agent in the production of bioethanol, replacing sulfuric acid, which is currently used to control bacterial contamination in the industrial process. Most interestingly, the developed process uses sugarcane molasses as the raw material for the bioextraction of chitin, the precursor of chitosan, from shrimp waste. This offers the possibility of producing chitosan in the plant itself, according to the concept of circular economy.

The results were published in the Journal of Polymers and the Environment.

“Chitosan is derived from chitin, a polysaccharide found in the cell walls of fungi, in the shells of crustaceans [such as shrimp and crabs] and in insects. To obtain chitosan, chitin must undergo a process called deacetylation, in which the acetyl groups [-COCH3] are removed from the molecule. In the conventional method used in the industrial production of chitosan, chitin is extracted using strong acids or bases. The great novelty of our study is that instead of this chemical route, we’ve developed a completely biological process, extracting chitin from shrimp shells through the fermentation of sugarcane molasses by the bacterium Lactiplantibacillus plantarum, with the addition of a nitrogen source,” Sandra Regina Ceccato Antonini, professor at the Department of Agroindustrial Technology and Rural Socioeconomics at UFSCar and coordinator of the study, told Agência FAPESP.

Methodology

The researcher describes the process step by step. In the first step, to obtain chitin, the shrimp waste is placed in the fermenter along with sugar cane molasses, lactic acid bacteria and a nitrogen source. The microorganism ferments the molasses, producing lactic acid and proteases. These substances release the chitin from the waste. After three days, the chitin is obtained by filtering and drying.

In the second step, chitin undergoes a deacetylation process, resulting in chitosan. Although there are also biological options for this second step, they were not explored in this study. Deacetylation was still carried out by chemical means.

“What we did was to manage this second chemical step in such a way that we produced both a high-molecular-weight chitosan and a low-molecular-weight chitosan. Why? Because each serves a different purpose. Low-molecular-weight chitosans generally have greater antimicrobial activity, while high-molecular-weight chitosans, that is, those with longer chains, are better for making polymeric films,” Antonini says.

The study resulted in protocols for the production of high-quality films, microspheres that can be used as drug carriers, and, most importantly, a natural antimicrobial that can replace sulfuric acid in the ethanol industry. It should be remembered that sulfuric acid is highly corrosive. Chitosan is a more environmentally friendly option.

“There are also market issues. At the time of the pandemic, there was a shortage of sulfuric acid, and that sort of caused desperation among people in the sugar and alcohol sectors, who came to me asking for an alternative because they didn’t know what else to do. Well, chitosan is that alternative. And its use in the ethanol industry is the great novelty of our study because it showed antimicrobial activity comparable to that of sulfuric acid,” the researcher emphasizes.

The comparison of the performance of the two agents is the subject of another article already submitted for publication. It should also be noted that the chitosan used in solution as an antimicrobial and for the production of films and microspheres is not purified, which reduces the cost of obtaining the polymer.

In addition to its potential in the bioethanol industry, the chitosan developed by the UFSCar-Araras team has demonstrated antifungal activity against agricultural pathogens such as Alternaria alternata (which causes Alternaria blotch), Fusarium sp. (fusariosis or dry rot) and Geotrichum citri-aurantii (sour rot). This property suggests its use as a natural biopesticide in agriculture, reducing the need for synthetic fungicides.

Although the economic viability of replacing sulfuric acid still needs to be analyzed, the research paves the way for a more sustainable approach to ethanol production. “If we think about a biorefinery model, there’s the prospect of producing chitosan within the sugar and ethanol plant itself,” the researcher suggests.

The research is the result of the doctoral thesis of Isabella Carvalho Tanganini, which she defended at the Luiz de Queiroz College of Agriculture of the University of São Paulo (ESALQ-USP) in June 2024. The first author of the article, Tanganini was supervised by Antonini. And part of her thesis was developed in collaboration with Professor Andréia Fonseca de Faria, a researcher at the University of Florida, in the United States, who co-authored the article.

The work was supported by FAPESP through two projects (18/19139-2 and 22/03293-8).

The article “Chitin and Chitosan Production from Shrimp Wastes by a Two-Step Process Consisting of Molasses-Based Lactic Fermentation and Chemical Deacetylation: Insights into the Antimicrobial, Microsphere and Film-Forming Properties of Chitosan” can be accessed at: link.springer.com/article/10.1007/s10924-024-03365-8.

Source: https://agencia.fapesp.br/54145