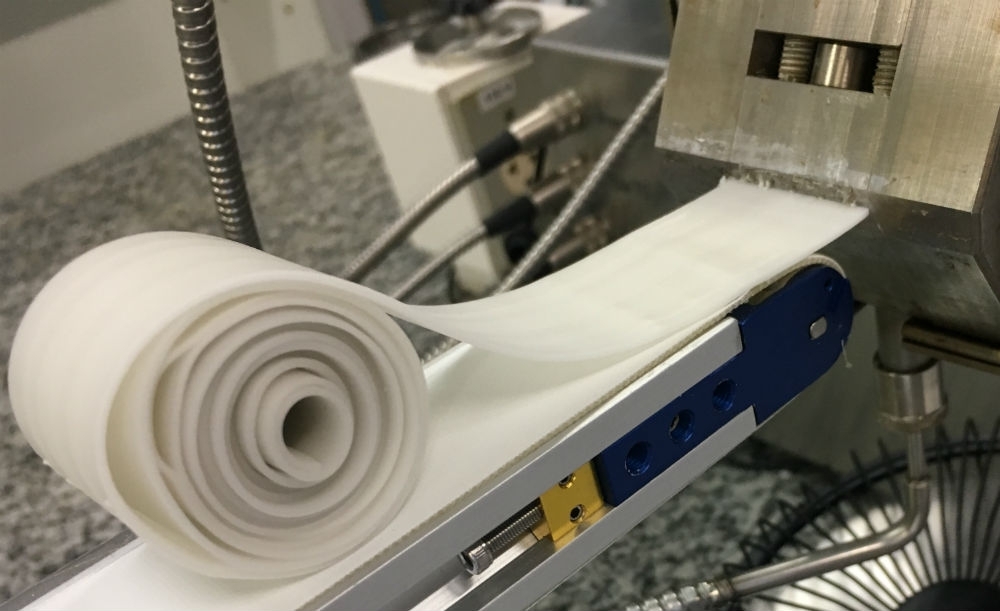

Scientists affiliated with the Food Research Center in Brazil are working to improve industrial feasibility of disruptive technologies such as the packaging that warns costumers when food starts spoiling (biofilm made from cassava starch; photo: Bianca Chieregato Maniglia / FoRC)

Published on 05/12/2021

By Maria Fernanda Ziegler | Agência FAPESP – Innovative packaging solutions may soon protect food products from the action of microorganisms, warn customers if products are not fit for consumption, and reduce the immense amount of plastic used by the industry.

These features will be implemented with the smallest possible impact on the environment, predict researchers affiliated with the Food Research Center (FoRC) hosted by the University of São Paulo’s Engineering School (POLI-USP) in Brazil. FoRC is a Research, Innovation and Dissemination Center (RIDC) funded by FAPESP.

“After years of research leading to new product launches, we’re now also able to ramp up production and above all think about how to bring these packaging products to market at competitive prices,” said Carmen Tadini, Full Professor at USP, head of POLI-USP’s Food Engineering Laboratory, and FoRC’s head of technology transfer.

Tadini explained that her laboratory has a twin-screw extruder, which is used both to test new materials and for large-scale continuous production. It was purchased with funding from FAPESP’s Multi-User Equipment Program (EMU) so that it can be used by researchers from other universities as well as entrepreneurs, in accordance with a facility-type model.

“Previously, we developed packaging products in small quantities, for research only,” Tadini said. “Now, however, although this machine is for laboratory use, it can be considered a workstation that analyzes a great many parameters for mass production processes.”

To develop competitively priced, sturdy packaging for mass production, the FoRC researchers are working on three key projects. One focuses on packaging that is more biodegradable than conventional products. The others study the feasibility of using substances that interact with food to prolong its shelf life (active packaging) and mechanisms to detect deterioration (smart packaging).

“We haven’t yet succeeded in developing plastic film with all the desired characteristics. That’s why we’re working on three lines,” Tadini said.

POLI-USP’s Food Engineering Lab has been developing packaging made from plants for some years. The most promising so far involves cassava starch biofilm.

“No one has ever succeeded in developing a plastic packaging technology that results in 100% biodegradable material, but the active and smart packaging products we’ve developed at our lab can be produced with a higher percentage than ever of biodegradable raw material,” Tadini said.

Packaging that prevents bread from spoiling in a short period is an example. To produce it, the researchers discovered a technique for adding cinnamaldehyde, the main fungitoxic component of cinnamon bark oil, to cassava starch biofilm.

“The product extends the shelf life of bread. We see it at least partially replacing potassium sorbate, which is widely used by the baking industry as a preservative,” Tadini said.

This active packaging product would cost only 12% more than the plastic commonly used to package bread, according to a study performed by Tadini’s laboratory, based on the cost of the raw material alone.

“In this study, we didn’t calculate the cost of producing the bread, as we’d need an industrial partner to work out the logistical impact of the extra shelf life in terms of inventory and transportation, for example,” she explained.

Smart warning

The researchers have also developed a version of the cassava starch biofilm additivized with anthocyanin, the red-blue or purple pigment in grapes, cabbages, and other kinds of fruit and vegetable.

“We discovered that the pH of dark red and purple foods changes as they deteriorate. They become more basic and change color. We had the idea of using this property of anthocyanin from grapes to develop innovative meat and fish packaging,” Tadini said.

Spoilage of meat or fish begins, she added, with the release of enzymes by microorganisms. The enzymes break down proteins, which in turn releases nitrogenated bases.

“Nitrogen is a common element in protein amino acid chains, and nitrogenated bases are volatile, so plastic biofilm with anthocyanin can signal whether the food product is fit for consumption,” Tadini said.

The packaging is purple when the pH is low and there is no deterioration. “The food’s pH rises as it spoils. Nitrogenated bases are more alkaline, and the higher pH changes the color to dark gray,” Tadini said.

Development of the packaging product with this signaling capability has overcome the main obstacle to industrial feasibility: preventing degradation of the raw material when it comes into contact with the high temperatures that occur in the extrusion process used to make plastic film.

“We’re very close to solving the equation,” Tadini said. “It’s an innovation. So far, no one has developed a technology that results in a commercially viable and 100% biodegradable flexible film.”

Source: https://agencia.fapesp.br/30731