The technique was developed at the Federal University of São Carlos (UFSCar) in São Paulo state, Brazil, and could impact the manufacturing of batteries, smartphone screens and other devices (photo: CeRTEV)

Published on 06/19/2023

FAPESP Innovative R&D* – Researchers affiliated with the Vitreous Materials Laboratory (LaMaV) at the Federal University of São Carlos (UFSCar) and the Center for Research, Education and Innovation in Vitreous Materials (CeRTEV) have developed, tested and filed for a patent on a novel route to obtain glass ceramics by ultra-fast crystallization of glass.

CeRTEV is hosted by UFSCar and is one of the Research, Innovation and Dissemination Centers (RIDCs) funded by FAPESP.

The technology has the potential to diversify the properties and applications of this class of materials, already present in smartphone screens, cooktops, and solid battery electrolytes, among other devices. So far, apart from research labs, the technique, known as flash-sinter crystallization, has been used only by one company in the world to produce ceramics, but not glass ceramics.

Glass-ceramic materials are obtained through controlled crystallization of base glass. In this process, glass is heated to a temperature high enough to stimulate crystals to nucleate throughout the glass. The temperature is then increased to induce growth of the nuclei and crystallize the remaining glass so that the atoms are spatially organized in patterns that are repeated throughout the material. Controlling this organization process is a challenge and can take hours by the classical glass-ceramics route.

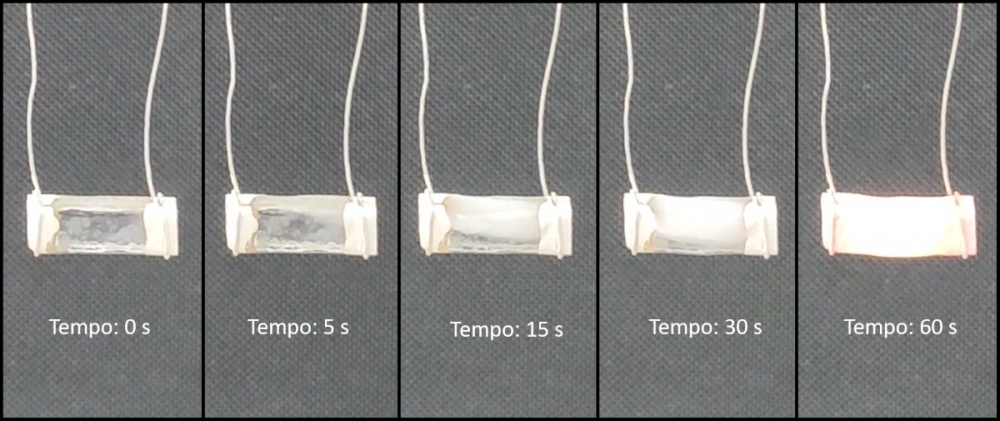

The researchers at LaMaV used flash-sinter crystallization for its exceptional speed and succeeded in producing dense glass-ceramic material in seconds. Besides speed, the temperature required is very low, saving a considerable amount of energy.

The novel technique was brought to LaMaV by João Vitor Campos, currently a postdoctoral fellow at the lab with a scholarship from FAPESP. He studied it as part of his PhD research, completed in 2020 at the University of São Paulo (USP).

However, the technique was previously used in ceramic materials only for sintering (converting ceramic powder into a solid object by compacting and heating). The difference in the UFSCar study was concurrent sintering and crystallization of glass powder, achieved through the development of software that controls electric field and current with precision while the vitreous material is being heated in order to transform it into glass-ceramic material.

To test the procedure, Campos obtained glass-ceramic material with the ion conductivity required for use in energy storage devices, but the invention can lead to novel materials or optimization of existing ones via enhanced properties and hence a wide array of applications.

Besides these applications, the researchers continue to investigate use of the technique with the aim of optimizing other characteristics of the materials obtained – such as the contours of grains with optimized electrical conductivity and orientation during crystallization – and different types of precursor glass from those used at present.

Companies interested in licensing the technology and partnering in this development process should email UFSCar’s innovation agency at inovacao@ufscar.br or call +55 16 3351-9040.

*With information from UFSCar’s Institute of Science Culture.

Source: https://agencia.fapesp.br/41682