Image: ACW

Published on 12/09/2024

By Roseli Andrion | Agência FAPESP – It is common for industries that produce items for human consumption (such as food, drinks, medicines and others) to use stainless steel containers to process them. This metal is well known for its resistance and ease of cleaning and maintenance, and this greater resistance to corrosion makes it the preferred choice when it comes to avoiding the release of chemical elements in food and medicines.

This characteristic is inherent to stainless steel: one of its components, among other metals, is chromium, which provides the formation of a natural passive protective film when the stainless steel is exposed to air. Because chromium has a strong affinity for oxygen, it reacts to form stable oxides and hydroxides that adhere to the surface of the metal. The formation of this invisible chromium oxide film is known as natural passivation, and it is this process that prevents stainless steel from corroding.

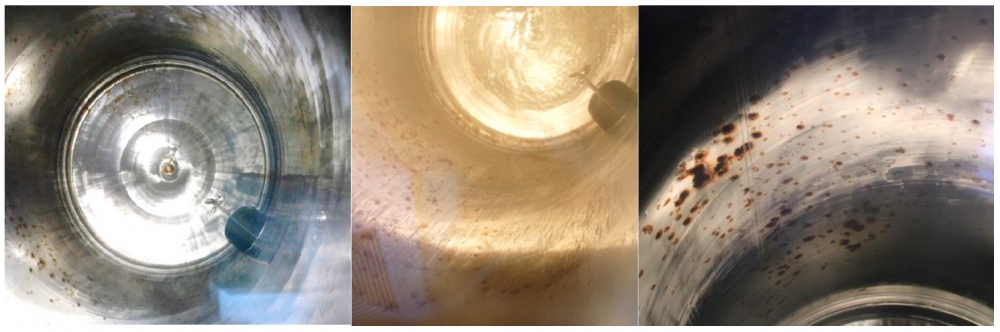

This makes it the best material for preventing contamination by microorganisms and other substances. In practice, however, the oxidation reaction – and consequent corrosion – in the food and pharmaceutical industries is inevitable, even if it takes longer. Over time, protein from the product being processed adheres to the metal container, the passive film (initially rich in chromium) becomes more iron-rich, and the stainless steel oxidizes and releases rust.

This reality is not limited to one country or another: industries all over the world face the same problems. Aware of this situation, materials engineer Luis Henrique Guilherme, researcher and engineering manager at ACW, a startup based in Araraquara (São Paulo state, Brazil), had the idea of developing a solution for it: an inspection device that scans the passivity of a stainless steel surface.

The device uses electrochemical microcells to characterize the resistance of stainless steel surfaces. “Some companies only detect contamination when they perform a microbiological analysis at the end of the process,” Guilherme points out. “When contamination is detected, in some cases the material can be reprocessed, but often it has to be thrown away – millions of dollars are lost.”

With support from FAPESP’s Innovative Research in Small Businesses program (PIPE), the company has developed portable equipment that allows stainless steel surfaces to be characterized directly in industry using electrochemical microcells. “This isn’t new: it’s been around since the 1990s,” he says. “But before that, it was a device the size of a table. The evaluation had to be done in a laboratory and, for an industry, it’s unfeasible to take tanks, reactors and pipes to a test bench.”

The engineer explains that the device detects alterations in a preventive way and allows the stainless steel surface to be treated so that it remains suitable for use. This process is called chemical passivation and consists of restoring the surface to prevent the material from corroding due to biofilm adhesion.

In some industries, stainless steel containers are used until they are damaged. Only then are they restored or replaced. “With the device we’ve developed, it’s possible to go to the industry and monitor the quality of the stainless steel surface that comes into contact with food products and medicines to quantify its degree of passivation.”

This ensures that the material is noble enough to be used. It is then monitored over time, and when it reaches the minimum acceptable level of passivation, the treatment can be repeated – before biofilm adhesion and localized corrosion occur.

The need for passivation depends on a number of factors, particularly the type of industry. While a dairy company may need treatment every 24 to 36 months, a fermentation company may need the process every six to 12 months – because it has more aggressive ingredients. “There’s no single parameter. You have to monitor the degree of conservation to determine the needs of each process.”

Galvanostatic passivation

After developing the ability to quantify the resistance of a surface that is going to process food and medicines, experts decided to create a simpler way to passivate it. Traditionally, this treatment is done by immersion in or spraying a chemical product – usually nitric acid – to restore the passive film.

Industrial chemical processing is very aggressive to the natural passive film, which isn’t resistant. “When it’s removed, corrosion occurs. Chemical passivation removes some of the iron in the film and increases the presence of chromium. In the literature, a ratio of 1.3 chromium to 1 iron is the minimum required. Often, when analyzing industrial equipment, ratios of 0.5 to 0.8 are found – in other words, they don’t meet the industrial processing criteria.”

The researcher explains that traditional treatment with nitric acid by immersion or spraying can bring the ratio of chromium to iron on the surface of stainless steel to 1.5, which is higher than the minimum required. However, the startup’s team has developed an even more efficient option: galvanostatic passivation. “This procedure greatly improves the treatment of the stainless steel surface by combining an acid solution with a certain current density. With it, we achieve a ratio of 2.5. This is a much better result than the traditional treatment.”

Another advantage of the ACW system is the use of citric acid, with a formulation developed by the startup’s team. “The best immersion treatment uses nitric acid, which is extremely dangerous to handle. Operators are in direct contact with this product, and if a hose or valve bursts, for example, it could cause a serious accident. In addition, it’s difficult to treat nitric acid to release the waste into the environment.”

With galvanostatic passivation, on the other hand, in addition to superior surface protection, effluent treatment is simpler and more economical, and there is no risk to the operator. “In conventional passivation, the concentration of chemicals, such as nitric acid, is 15% to 20%. With galvanostatic passivation, I use a weaker (and cheaper) acid at a concentration of 7%. This way, the operating costs are lower, the result is better, and there’s no risk to the operator or the environment.”

Today, the startup offers a solution that includes measuring surface resistance, treating the stainless steel to protect it from chemical attack, and periodic monitoring to find out when the passivation needs to be redone. “Without this monitoring, companies don’t know when to intervene. If they wait for corrosion to occur, it’s much more expensive to repair,” he says. “With monitoring, there’s no anticipated cost or risk of equipment failure.”

The specialist points out that this monitoring guarantees savings for the industry. “When you know the chemical quality of the passive film, you can define when to act: you don't intervene prematurely or overdo it. Biofilm fouling, for example, can cause micro-holes in the surface, in which case mechanical intervention is required, which is more costly.”

In addition, regular monitoring and treatment of the surfaces extends the useful life of the equipment. Without this care, the equipment may need to be replaced in six to eight years. With preventive measures, it can be used for up to 30 years. “In other words, this surface treatment is very beneficial to the industry from several perspectives.”

In terms of cost, Guilherme says that an industry that spends, say, BRL 50,000 every two years on this surface treatment will pay BRL 300,000 if, instead of taking preventive action, it lets the equipment fail. “And if it loses a production batch of, say, one month, it could lose up to BRL 1.5 million. The cost of monitoring is negligible compared to the potential losses, because it has maximum reliability.”

Operating abroad

Guilherme says that ACW’s solution is unique and has no competitors in the world. “Based on this electrochemical microcell project, in 2023 we established a subsidiary in Canada in partnership with McMaster. We showed that we could measure the quality of stainless steel and present advanced parameters, with useful information on the thickness and resistance of the passive film.”

The startup also has collaborations in Germany and the United Kingdom, at the University of Manchester. “This was possible because galvanostatic passivation is something that nobody else in the world is doing, and we’re already using it in industrial conditions. There’s no increase in cost, but there’s an increase in quality and it improves competitiveness.”

ACW was one of the companies selected to participate in a business mission to FAPESP Week Spain, which took place in Madrid on November 27th and 28th.

Source: https://agencia.fapesp.br/53530