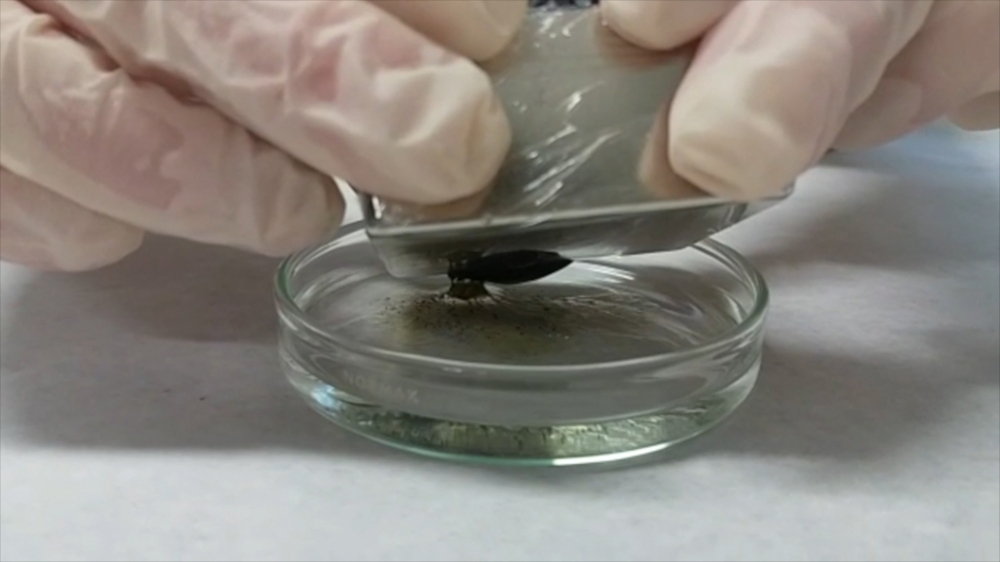

Collaborative research between Brazilian universities combined magnetic materials and biomass residues to create nanoparticles that remove heavy and light oil from surface water with great efficacy (image: UNIFESP)

Published on 05/04/2021

By Elton Alisson | Agência FAPESP – Researchers at the Federal Universities of São Paulo (UNIFESP), Sergipe (UFS) and São Carlos (UFSCar) in Brazil are developing magnetic materials to help remove crude oil from the sea surface in the aftermath of oil spills such as the one that polluted beaches along part of the Brazilian coast in recent months.

The materials are hybrids, comprising ferromagnetic nanoparticles and biomass residue. Laboratory tests have shown that they can indeed remove crude oil and other types of oil, such as motor oil or ship engine lubricant, with more than 80% efficacy.

The results of the project, conducted at UNIFESP with support from FAPESP, will be tested in field experiments in the state of Ceará (Northeast Brazil) to gauge the material’s beach cleanup effectiveness.

“These magnetic nanoparticles can be used not only to clean beaches but also by oil companies to recover spilled crude. Another advantage is that they’re eco-friendly because they’re made of compounds found in nature,” Geórgia Labuto, a professor at UNIFESP in Diadema told Agência FAPESP.

The particles developed by the UNIFESP group combine magnetite (one of the main iron ores) with yeast biomass residue from the ethanol industry’s fermentation processes. The combination gives rise to bionanocomposites – nanometric hybrid materials obtained from renewable sources. A nanometer is one billionth of a meter.

According to the researchers, the material’s low cost and enhanced decontamination efficacy are due to the fact that by depositing the particles of magnetite on the surface of the biomass, they were able to maintain magnetite’s magnetic properties while at the same time increasing the surface area of the contact between the material and the oil.

“Use of an agroindustrial waste lowers the cost and contributes to the production of a larger mass of magnetic material with a smaller quantity of reagent. By applying a magnetic field to an aqueous medium in which these particles are dispersed, it’s possible to remove them together with the oil or other fluid to which they adhere,” Labuto explained.

Removal capacity

In a study published in the Journal of Environmental Management, the researchers evaluated the capacity of the bionanocomposites to remove new and used motor oil, as well as light crude oil with an API of 28 degrees (American Petroleum Institute gravity, or API gravity, is a measure of how heavy or light oil is compared to water: the lower the API, the higher the oil’s density), from water.

The results show that the material removed 55%-89% of the new motor oil and crude oil in the samples and 69% of the used motor oil after contact for two minutes.

The researchers also found that the removal of these compounds from the water by the material was a predominantly physical phenomenon. Simply put, the thrust of the attraction exerted by a magnetic field such as that produced by a magnet is so intense that it drags out the particles and hence the oil that has adhered to their surface.

In the case of an oil spill, the method proposed by the researchers consists of using the particles to eliminate the crude after it has been removed from the water surface by a skimmer, a mechanical device similar to a conveyor belt. The floating oil sticks to the belt and is conveyed into the vessel.

“Our aim is to use the material to remove the oil collected by the skimmer and separate it from the water,” Labuto said.

The UNIFESP researchers have also used powdered cork to develop bionanocomposites.

In another study, also published in the Journal of Environmental Management, they evaluated the efficacy of two types of particle, one containing yeast biomass and the other cork powder, in removing crude with different APIs, including heavy oil (API 10) and light oil (API 45), from the surface of fresh and sea water, with and without agitation of the water.

The magnetic nanomaterials exposed to the oil in the water were removed using a neodymium magnet.

The results of the analysis showed that the magnetic nanocomposites containing yeast biomass recovered a higher proportion of the oil. In addition, the rate of oil removal by this magnetic material increased as the API decreased, so it was possible to predict the amount of oil that could be recovered in accordance with its density.

“The higher the API, the lighter the oil and the greater its commercial value,” Labuto explained.

By varying the mass of bionanocomposite, the researchers were able to remove 100% of all the types of oil used in the study, regardless of their API gravity.

“These magnetic composites can be used in various oil removal cycles before recovery and also after recovery because they retain their magnetic properties,” Labuto said.

Other materials

A group of researchers at UFS, in collaboration with colleagues at UFSCar, have developed hybrid organic-inorganic powder-membrane matrices containing biomass and cobalt ferrite, also on a nanometric scale, under the aegis of a postdoctoral research project supported by FAPESP.

The powders used to form the organic phase were synthesized from the following biomass wastes: coconut mesocarp, sugarcane bagasse, sawdust, and water hyacinth.

In a study also published in the Journal of Environmental Management, the researchers report the results of laboratory tests that measured the efficacy with which these matrices remove heavy crude from water surfaces by magnetic attraction.

The materials were developed by Graziele da Costa Cunha, a postdoctoral fellow of UFS, with supervision by Professor Luciane Pimenta Cruz Romão.

The analysis showed that the powder made from sugarcane bagasse was most effective in removing oil, with the capacity to adsorb 85%. According to the authors, this was due to the fibrous nature of the raw material.

The amount of oil removed by the membranes was equivalent to up to 35 times their mass.

When both materials were used simultaneously, the amount of oil removed was 45 times their mass, and the bagasse powder’s adsorptive capacity increased by 23%.

This high adsorptive capacity was related to the barrier formed by the powder, preventing the oil patch from spreading and permitting its homogenous removal, according to the authors.

“We also observed that the distribution of the cobalt ferrite nanoparticles in the biomass residues increased the speed of oil removal,” said Caio Marcio Paranhos da Silva, a professor at UFSCar and principal investigator for the project. “The materials removed the oil from the surface of the water in the samples in only 2 seconds.”

By means of a research internship at the University of Aveiro in Portugal, also with support from FAPESP, postdoctoral scholar José Arnaldo Santana Costa, supervised by Paranhos, now plans to include cobalt ferrite in nanoparticles he developed from rice hulls during his PhD research.

The goal is to produce a new membrane that can remove not only crude from surface water but also polycyclic aromatic hydrocarbons (PAHs), reducing the toxicity of oil spills as well as eliminating the heavy oil itself.

“These substances, which are present in heavy oil, are highly toxic and carcinogenic,” Silva said. “They represent a major risk for the people who volunteered to remove the oil from beaches in the Northeast without proper protection.”

The article “Oil spill cleanup employing magnetite nanoparticles and yeast-based magnetic bionanocomposite” (doi: 10.1016/j.jenvman.2018.09.094) by Karina B. Debs, Débora S. Cardona, Heron D.T. da Silva, Nashaat N. Nassar, Elma N.V.M. Carrilho, Paula S. Haddad and Geórgia Labuto can be retrieved from: www.sciencedirect.com/science/article/pii/S0301479718311046.

The article “A comparison study of cleanup techniques for oil spill treatment using magnetic nanomaterials” (doi: 10.1016/j.jenvman.2019.04.106) by D.S. Cardona, K.B. Debs, S.G. Lemos, G. Vitale, N.N. Nassar, E.N.V.M. Carrilho, D. Semensatto and G. Labuto is at: www.sciencedirect.com/science/article/pii/S0301479719305730.

The article “Removal of heavy crude oil from water surfaces using a magnetic inorganic-organic hybrid powder and membrane system” (doi: 10.1016/j.jenvman.2019.06.050) by Graziele da Costa Cunha, Nalbert C. Pinho, Iris Amanda Alves Silva, José Arnaldo Santana Costa, Caio M.P. da Silva and Luciane P.C. Romão is at: www.sciencedirect.com/science/article/pii/S0301479719308527.

Source: https://agencia.fapesp.br/32264