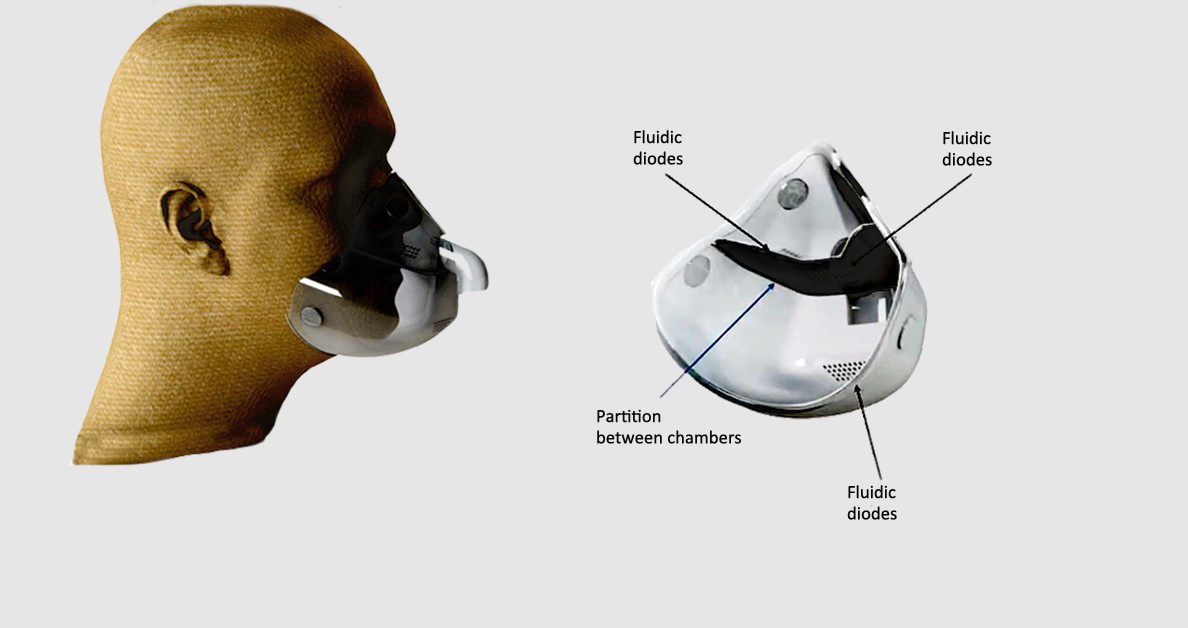

The new mask, which has already been patented, was designed with a partition between the nasal and oral cavities (image: Auspin/reproduction)

Published on 06/18/2024

Agência FAPESP* – A more efficient and comfortable mask for the treatment of sleep apnea is being developed by researchers at the Research Center for Greenhouse Gas Innovation (RCGI) – an Engineering Research Center (ERC) created by FAPESP and Shell at the University of São Paulo’s Engineering School (POLI-USP) in Brazil.

Using the same technology used in a project on gas turbines, the researchers created a model whose differential is to avoid the “choking on air” that occurs with continuous positive airway pressure (CPAP), the device used to treat the disease that pumps air into the patient’s airways.

Sleep apnea is characterized by repeated obstructions of the throat during sleep, causing pauses in breathing. According to a survey by the Sleep Institute, a clinical, research and teaching network in São Paulo focused on sleep medicine, the problem affects around a third of Brazilians. When it occurs, the muscles in the throat close up and only return to normal when the person wakes up, which can happen several times during sleep.

This condition not only negatively affects the quality of sleep, but can also cause heart disease due to the constant changes in oxygenation. In cases of moderate or severe apnea, one of the treatment recommendations is the use of CPAP, according to the Brazilian Society of Pulmonology and Phthisiology.

“Many people abandon CPAP treatment because they choke on the air that’s being directed from the mouth to the nasal cavity. What’s more, when the choking occurs, CPAP also stops working,” says Vitor Bortolin, a doctoral student in mechanical engineering at POLI-USP and a researcher at the RCGI. ”This happens because people with respiratory problems tend to breathe through their mouths, and when they do, they transfer the air to their noses, which is the way the body recognizes as correct. When they do this, they exert force to breathe through their mouths again, which causes choking, replicating what happens to the person when they don’t use the device,” explains Bernardo Diniz Lemos, also a doctoral student at POLI-USP and a researcher at the RCGI.

Both are part of the group of researchers leading the project, coordinated by Professor Julio Meneghini, Scientific Director of the RCGI. Although it is a separate project within the scope of the RCGI, the technology used is the same as that used in the project “Intelligent labyrinth seals for mitigating greenhouse gas emissions in pneumatic machines,” which aims to develop technologies to reduce as much as possible the leakage of gases such as carbon dioxide and methane in the compressors and turbines of these machines.

Innovative solution

The new mask, which has already been patented, was designed with a partition between the nasal and oral cavities. It uses an engineering technique applied in gas industry equipment to circulate air between the two cavities. This keeps the air pressure in the nose and mouth at the ideal level, which should be about 10% higher in the nose.

“We use a technique called a fluidic diode, which is a valve, similar to a pipe, with no moving parts and curved filaments, designed to facilitate the transmission of air from the nose, where it comes in, to the mouth, where the air goes out, and to make it difficult for the air to go back from the mouth to the nose. That way, when the person opens their mouth, the valve will prevent the air from going to the nose, which prevents choking,” explains Bortolin.

The valve and filaments were made on a 3D printer and installed on a plate that separates the two cavities. The plate is made of plastic and covered with silicone padding. The design and material properties make the device much more comfortable and easier to use, whether at home or in a hospital environment.

Challenging problem

“The fluidic diode is the main innovation of the project, because there are already models that use a partition or two chambers, but the problem is that you have to use two air pumps to make it work. This ends up significantly increasing the cost of the product, as well as doubling the noise generated by the machine,” says Lemos.

Previous studies also considered models with a single pump and two valves. “This also created problems because the valves had to be large and contain moving parts that could be swallowed by the patient. In addition, it was difficult to maintain humidity and prevent the proliferation of bacteria, which would cause the valves to become ‘clogged’ with these microorganisms and stop working,” adds Bortolin.

The researchers now plan to test the fluidic diode model in humans. Projections made on geometric models already indicate that air circulation should benefit. “We were able to calculate the number of fluidic diodes and estimate how the air circulation would work by comparing these values with those of other applications of this technology in gases, which is within the ideal range,” explains Bortolin.

A demonstration of how the technology works can be seen in a video available on USP’s Inovação YouTube channel.

* With information from the RCGI.

Source: https://agencia.fapesp.br/51989