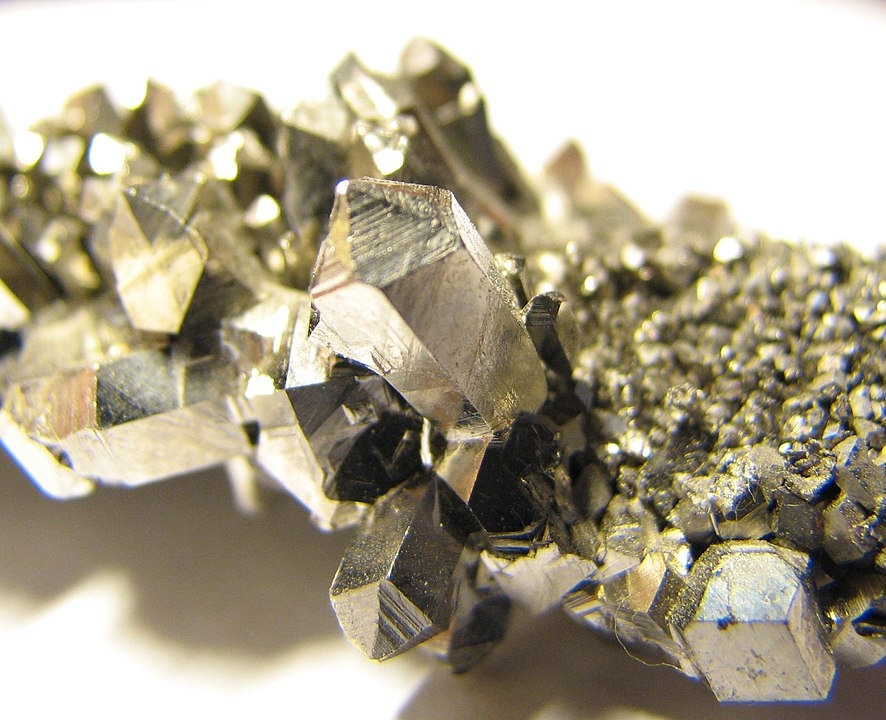

Glycerol fuel cell can replace batteries in cell phones and laptops, and could be used in future to run electric cars and supply power to homes (niobium crystals. image: Artem Topchiy / Wikimedia Commons)

Published on 05/04/2021

By José Tadeu Arantes | Agência FAPESP – Brazil is the world’s largest producer of niobium and holds about 98% of the active reserves on the planet. This chemical element is used in metal alloys, especially high-strength steel, and in an almost unlimited array of high-tech applications from cell phones to aircraft engines. Brazil exports most of the niobium it produces in the form of commodities such as ferroniobium.

Another substance Brazil also has in copious quantities but underuses is glycerol, a byproduct of oil and fat saponification in the soap and detergent industry, and of transesterification reactions in the biodiesel industry. In this case the situation is even worse because glycerol is often discarded as waste, and proper disposal of large volumes is complex.

A study performed at the Federal University of the ABC (UFABC) in São Paulo State, Brazil, combined niobium and glycerol in a promising technological solution to the production of fuel cells. An article describing the study, entitled “Niobium enhances electrocatalytic Pd activity in alkaline direct glycerol fuel cells”, is published in ChemElectroChem and featured on the cover of the journal.

“In principle, the cell will work like a glycerol-fueled battery to recharge small electronic devices such as cell phones or laptops. It can be used in areas not covered by the electricity grid. Later the technology can be adapted to run electric vehicles and even to supply power to homes. There are unlimited potential applications in the long run,” chemist Felipe de Moura Souza, first author of the article told Agência FAPESP. Souza has a direct doctorate scholarship from FAPESP.

In the cell, chemical energy from the glycerol oxidation reaction in the anode and air oxygen reduction in the cathode is converted into electricity, leaving only carbon gas and water as residues. The complete reaction is C3H8O3 (liquid glycerol) + 7/2 O2 (oxygen gas) → 3 CO2 (carbon gas) + 4 H2O (liquid water). A schematic representation of the process is shown below.

“Niobium [Nb] participates in the process as a co-catalyst, assisting the action of the palladium [Pd] used as the fuel cell anode. The addition of niobium enables the amount of palladium to be halved, lowering the cost of the cell. At the same time it significantly increases the power of the cell. But its main contribution is a reduction in the electrolytic poisoning of the palladium that results from the oxidation of intermediates that are strongly adsorbed in long-term operation of the cell, such as carbon monoxide,” said Mauro Coelho dos Santos, a professor at UFABC, thesis adviser for Souza’s direct doctorate, and principal investigator for the study.

From the environmental standpoint, which more than ever should be a decisive criterion for technological choices, the glycerol fuel cell is considered a virtuous solution because it can replace combustion engines powered by fossil fuels.

Several other researchers participated in the study besides Souza and Santos: Paula Böhnstedt, supported by FAPESP via a scientific initiation scholarship; Victor dos Santos Pinheiro, supported by FAPESP via a doctoral scholarship; Edson Carvalho da Paz; Luanna Silveira Parreira, supported by FAPESP via a postdoctoral scholarship; and Bruno Lemos Batista, supported by FAPESP via a Young Investigator Grant.

The article “Niobium enhances electrocatalytic Pd activity in alkaline direct glycerol fuel cells” can be retrieved from: onlinelibrary.wiley.com/doi/abs/10.1002/celc.201901254.

Source: https://agencia.fapesp.br/31978