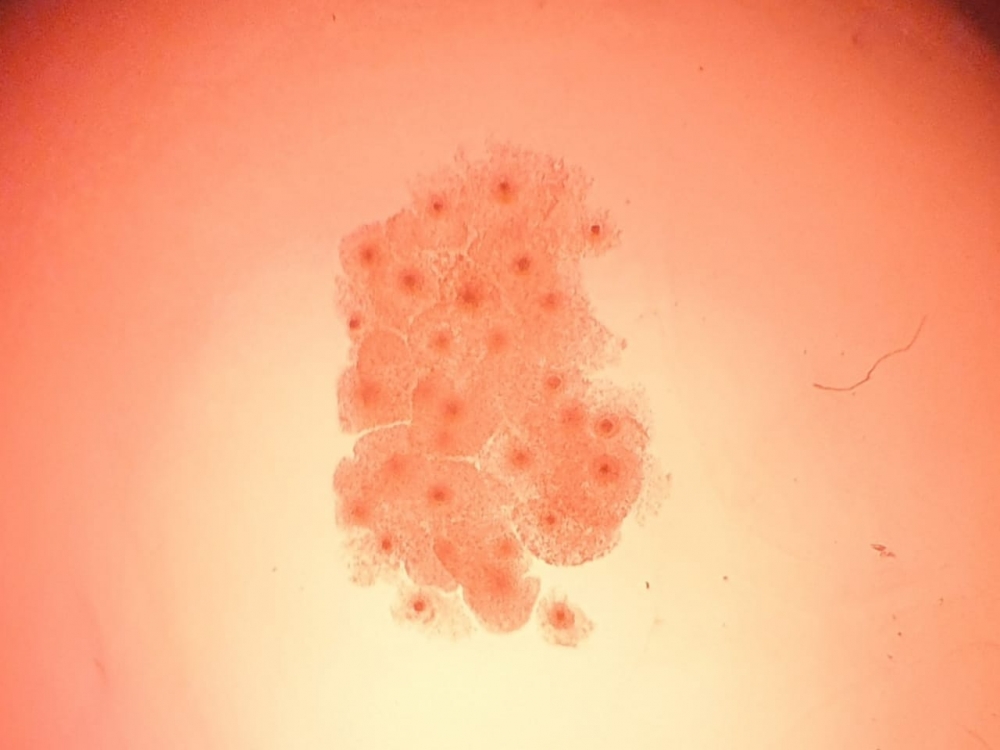

Image: Blastocell

Published on 05/20/2024

By Roseli Andrion | Agência FAPESP – Why are bovine embryos cultured on a two-dimensional substrate and not in a three-dimensional environment like the cow’s uterus? Raquel Zaneti Puelker, a veterinarian who specializes in bovine in vitro embryo production, used to ask herself this question all the time.

“In the conventional in vitro production [IVP] process, the embryo in the culture droplet often sticks to the bottom of the culture dish and tends to be flattened instead of spherical when removed. So I wondered whether this area of the embryo that sticks to the bottom of the dish and doesn’t come into contact with the environment may lose the ability to interact,” said Puelker, co-founder of Blastocell Biotechnologies, a startup based in Presidente Prudente (São Paulo state, Brazil).

This concern led her to consider creating a more appropriate environment for embryo IVP. “If we could grow the embryo in a way more closely resembling what happens inside the cow’s uterus, it wouldn’t be flattened as it is on a two-dimensional substrate. Both the oviduct [the conduit for oocyte transfer to the uterus] and the uterus are three-dimensional, and the embryo interacts with their tissue,” she said.

Collaborating with Sarah Nunes and Anthony Castilho, Puelker embarked on a search for a substrate that mimicked the physiological model. “We aimed at a membrane made of non-toxic material that in theory should be highly suited to 3D embryo culture. We tested several materials and selected those to which the oocyte and embryo adapted best,” Puelker recalled.

In preliminary laboratory tests, the technology produced good results in terms of maturation compared with conventional 2D culture. “We achieved an increase of at least 10% in embryo production. Our main goal is embryo quality, and that naturally translates into more gestations,” Puelker said.

The project is supported by FAPESP’s Innovative Research in Small Business Program (PIPE). The material is biodegradable and made from widely available raw material. The system can easily be implemented by commercial bovine embryo laboratories and increases IVP by 32%. “The most significant impact is verified in taurine breeds,” she said. “Cellular interactions are enhanced, and there are no adverse effects on oocyte quality.”

Another advantage of the system is the possibility of slow release of any factor, such as a protein or antioxidant, for example. “There are specific requirements during the development of the embryo, and this material permits controlled release of elements of interest,” she explained, adding that this is also useful with regard to the culture medium. “The medium should be optimized for each stage of development, and the 3D material facilitates this adaptability.”

In vitro and in vivo

According to Puelker, embryos developed in vivo are of better quality than those cultured in vitro. “There are several reasons for this, and one of them may be the method of culture. The primary goal is to ensure that IVP comes out as close as possible to in vivo production,” she said.

In vivo embryos usually have more viable cells, regardless of the animal species involved. “A great deal of progress has been made, but there are still deficiencies in the conversion of embryos produced in vitro into pregnancies. We believe small advances will take us closer to what happens physiologically,” she said.

Embryos produced in vitro are highly sensitive to cryopreservation, while those produced in vivo are much less so. The startup aims to ensure that its technique makes embryos obtained in vitro more viable so that they can reach the same gestation rates as those produced in vivo. Any rise in the percentage of pregnancies can represent a considerable increase in production, according to Puelker.

“If a breeder has 100 recipients prepared for embryo transfer, he’s invested in these animals and expects to get the largest possible number of pregnancies,” she said.

Ideally, the number of embryos delivered by the laboratory matches the number of recipients available. In addition, these embryos should produce the highest possible percentage of pregnancies. This is not always the case, however. Between 30% and 60% of in vitro embryos are converted into pregnancies, compared with up to 80% for in vivo embryos. “If we can raise this by 10% or 20%, for example, it means profit for the breeder,” she said.

It also means savings in the process of preparing the recipients. “On our farm, for example, we try to maintain sustainability. If we synchronize the cows and then have to resynchronize, we produce more refuse and end up wasting material. We try to consider the entire production chain. The higher the quality of the embryos, the less waste,” she said.

A model for each stage

IVP comprises several stages, and the startup’s team had to adapt the technique to each one. The first step entailed creating a methodology for oocyte maturation. “Good embryos can’t be produced unless the quality of the oocytes is good,” she said. A maturation system has been implemented using material produced by biodigesters. Testing is now imminent for the fertilization and embryo culture stages. The duration of embryo culture varies according to the species. Bovine embryos are transferred on day 6 or 7 (one or two more days are required for equine embryos).

The material used to contain the embryo is biodegradable and must remain adequate throughout each stage of development (maturation, fertilization and culture). In order to develop a system that can be used for different animal species, the material must behave suitably to whatever species the embryo belongs to. The system is also to be complete, requiring two more years of research.

“That’s my expectation because having defined the first stage we know how to handle the material. We had difficulties initially but made good progress. I believe the most daunting obstacles have been surmounted. Now the priority is adaptation to the various stages of embryo production,” she said.

The firm plans to use the technique to produce equine, ovine and swine embryos. “As well as meat production, swine farmers are currently investing in ‘minipigs’ for use in research and development of tissue for transplantation in humans. Swine embryos optimally produced in a system that promotes better cell quality will assure the production of more adequate animals,” she said.

The 2D dish or sheet is used worldwide, she added, and, although other R&D projects are in progress in the segment, the methods are different from those proposed by the firm. “There are models that use microfluidic technology to ensure the embryo doesn’t stay still on the surface, but I have yet to see any that use uterus-like malleable material,” she said.

The name of the firm is a portmanteau of “blastocyst” – the early stage of development of the embryo – and “cell”, representing the quality of its cells. “At the end of the day, that’s what we’re after: the quality of embryo cells,” she said.

Source: https://agencia.fapesp.br/51721