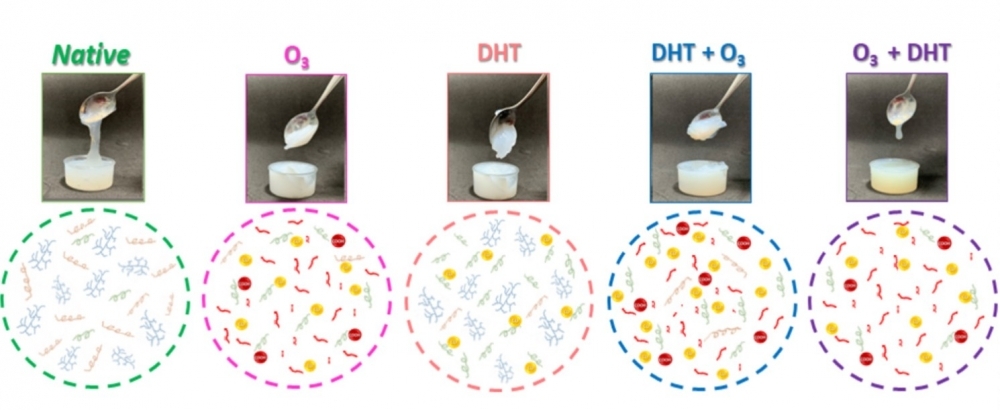

Methods considered emerging are environment-friendly and can be implemented now by industry in various segments (diverse treatments applied to cassava starch at ESALQ-USP; image: researchers’ archive)

Published on 01/03/2022

By Karina Ninni | Agência FAPESP – A group of researchers at the University of São Paulo’s Luiz de Queiroz College of Agriculture (ESALQ-USP) in Brazil have tested for the first time the joint application of two starch modification techniques that produce no residues or effluents, combining ozone and dry heat treatment (DHT). The scientists believe the results may contribute to an increase in the possible applications of cassava starch in different production processes. An article on the research is published in the International Journal of Biological Macromolecules.

Naturally present in plants, where it serves as a store of energy, starch is a key ingredient for the food, paper, textile, pharmaceutical and paint industries, among others, and is even used in oil drilling. Food engineer Pedro Esteves Duarte Augusto, who by the time of the research was affiliated with ESALQ-USP’s Center for Food and Nutrition Research (NAPAN), the starch modification techniques are designed to enhance the material’s properties for specific purposes.

“Our group has done a lot of work with gel formation, one of the most important properties of starch, both for the food industry and for other segments, such as pharmaceuticals, for example,” said Augusto, last author of the article and currently a professor at Université Paris-Saclay. The first author is PhD candidate Dâmaris Carvalho Lima. The other co-authors are other members of the ESALQ-USP research group, and colleagues affiliated with France’s Nantes-Atlantic National College of Veterinary Medicine, Food Science and Engineering (ONIRIS Nantes) and National Research Institute for Agriculture, Food and Environment (INRAE). Augusto and the group have been studying starch since 2015.

According to Augusto, the findings described in the article open up possibilities. “Native cassava starch gel is considered ‘weak’ compared to other starch gels, such as corn starch gel, for example, the most significant commercial starch gel right now. The cassava starch gel we obtained was even more consistent than corn starch gel. We expect this to contribute to an expansion of the market for cassava starch,” he said.

Stronger gels and more viscous pastes that form at lower temperatures are considered ideal in this area, Augusto explained. “In the case of corn starch used by cooks as a thickener, for example, you need to boil it to make a gel. We’ve successfully made gels from different starches at lower temperatures, thereby reducing energy expenditure to obtain the product. We’ve also found ways of forming gels with lower concentrations of starch,” he said.

In the case of this study specifically, conducted with FAPESP’s support, the group concluded that ozone treatment and DHT used separately or jointly were capable of extending the possible applications of native cassava starch. “We’d already been working with these two techniques separately, and in this study we combined them,” August said.

The research also received funding from the Brazilian government via the Coordination for the Improvement of Higher Education Personnel (CAPES) and the National Council for Scientific and Technological Development (CNPq), as well as the French program RFI Food for Tomorrow.

Differences

According to Augusto, most of the starch used commercially around the world comes from corn, rice, wheat, cassava or potato. The most widely used modification techniques involve the use of solutions such as sodium hypochlorite, an active ingredient of household bleach, and chemical reagents that require occupational health and safety precautions and produce effluents that must be treated before disposal. “These aren’t insurmountable obstacles. The products on the market are safe, but it’s always worth offering a different route,” he said.

The eco-friendly advantages of products obtained via modification with ozone and DHT may be more valued by some industries than others. “I believe they’ll appeal most to the food industry. Manufacturers may want to put this information on the packaging,” he said.

The two treatment techniques used one after the other made a huge difference to the end-product, he added. “Moreover, the order of their use completely changed the result. When we used DHT first and then ozone, we obtained a firmer gel. The gel was softer when we used ozone first. We don’t yet know why, but we have a few hypotheses based on the way the molecules are altered. What matters most is that each gel can be relevant in its way to different industries. That’s the best part of working with starch – there’s no such thing as a waste of time,” he said.

Other non-conventional starch modification techniques have been studied by the group besides the use of ozone and DHT. “Irradiation is one, as is ultrasound, but these are expensive and laborious. They’re very far from being adopted by industry in my view. Ozone and DHT are relatively cheap. Implementation isn’t highly complex, and the technology is ready to be used. All that’s needed is an economic feasibility study by the company or industry that wants to use them,” he said.

Method

The native cassava starch used in the study was a regular commercial product supplied by a large company, Augusto explained, adding that for the experiment described in the article he and the team produced ozone in the laboratory (in an ozone generator) by applying an electric discharge to a certain amount of oxygen with 95% purity. Ozone has three oxygen atoms and is unstable, tending to break down into the oxygen molecule with two atoms that exists in the air we breathe. “It’s a very powerful oxidant, widely used for microbial inactivation in water filters and swimming pools. In our case, it oxidizes the starch and rapidly degrades, which is excellent because the ‘waste’ from the reaction is oxygen,” he said.

In the ozone treatment, the sample was placed in a glass reactor into which ozone and oxygen were injected, processed for 30 minutes and constantly stirred.

For DHT, the researchers used a hot-air convective oven. “The air is heated electrically and warms the product as it passes through, except that temperature is much more precisely controlled than in a domestic oven. The starch sample was wrapped in aluminum foil and sealed to prevent loss of material,” Augusto said.

Novel sources

The group has three main lines of research, he explained: identifying and characterizing novel sources of starch, starch modification, and exploring possible applications, both novel and traditional. “In partnership with colleagues in Peru, we’re studying arracacha [Arracacia xanthorrhiza], an Andean root not too different from a parsnip. We’ve also investigated starch extracted from the seeds of uvaia [Eugenia pyriformis], a fruit native to the Atlantic Rainforest in Brazil. And we’ve signed a partnership to study Amazonian fruit residues,” Augusto said.

The group now wants to use these two modification techniques on other starches and with other process conditions in a search for additional functionality. “We’ll end up experimenting with applications of these starches in real products, such as bread or instant soup, for example. The food industry is the main focus, but we’re open to partnerships for other uses,” he said.

The article “Dual-process of starch modification: Combining ozone and dry heating treatments to modify cassava starch structure and functionality” by Dâmaris Carvalho Lima, Bianca Chieregato Maniglia, Manoel Divino Matta Junior, Patricia Le-Bail, Alain Le-Bail and Pedro Esteves Duarte Augusto is at: www.sciencedirect.com/science/article/abs/pii/S0141813020349710.

Source: https://agencia.fapesp.br/37638