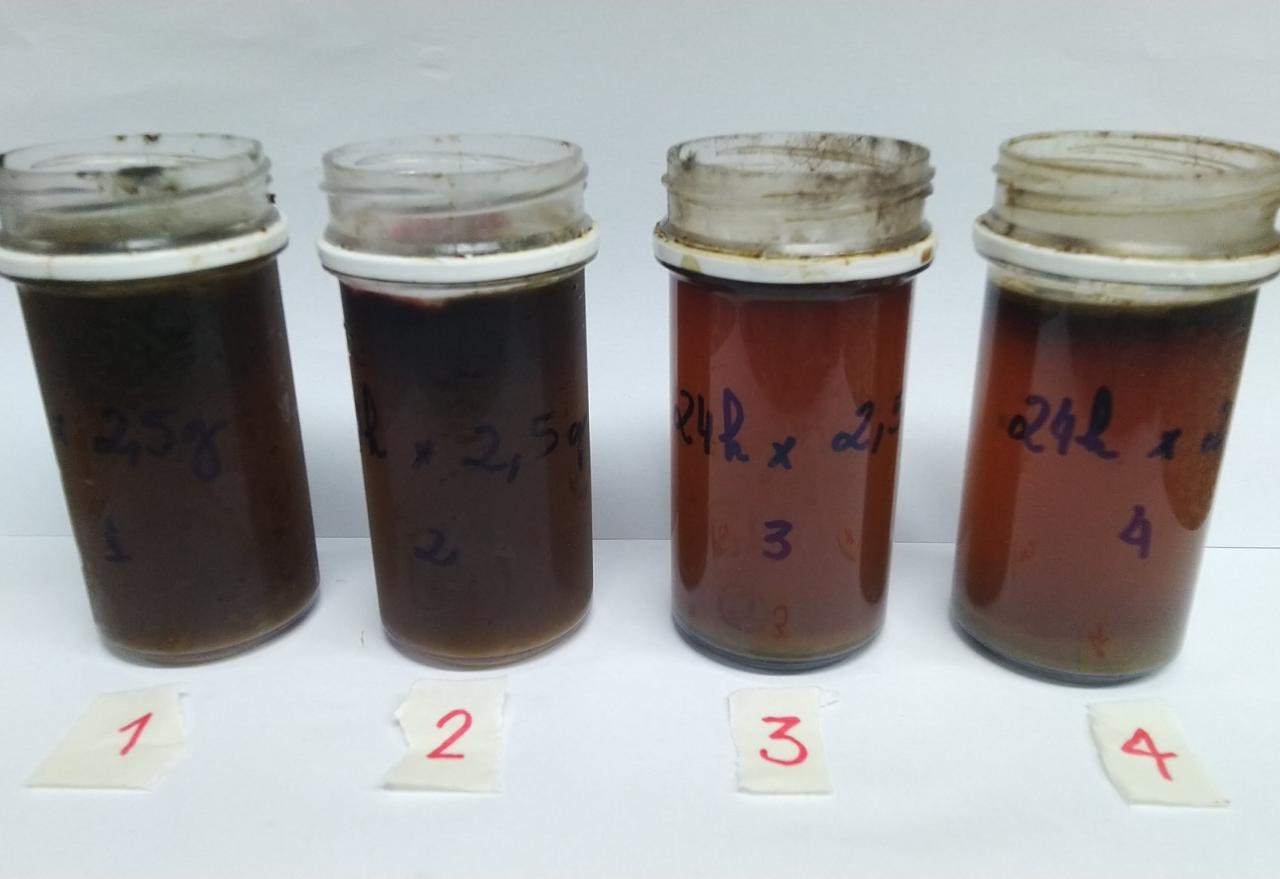

The ash was placed in a solution that mimicked vinasse to evaluate the methodology (photo: Milena Maria Antonio)

Published on 02/03/2025

By Karina Ninni | Agência FAPESP – Brazil accounts for 8% of global consumption of fertilizers, especially potassium, an essential nutrient for plant growth. About 96% of the potassium it consumes is imported, according to recent data from the federal government. However, this mineral can be obtained from sugar industry byproducts such as vinasse and bagasse.

“A hundred and fifty cubic meters of vinasse contains 340 kilos of potassium on average. Brazil imports this input, particularly potassium nitrate, and yet a huge amount is thrown away. That’s wasteful, but more importantly, it makes us vulnerable, not least to conflicts such as the war in Ukraine, which has been our supplier of the fertilizer for a long time,” said chemist Roselena Faez, full professor at the Federal University of São Carlos (UFSCar) in Araras, São Paulo state (Brazil).

With her students in the Program of Graduate Studies in Agriculture and Environment, Faez has been looking for ways to reuse potassium and nitrogen recovered from the huge amount of vinasse left over after sugarcane is processed by distilleries to produce ethanol (12-18 liters of vinasse per liter of ethanol).

In one of their experiments, Faez and master’s student Milena Maria Antonio used sugarcane bagasse ash to recover potassium and nitrogen from vinasse.

An article on the study, which was supported by FAPESP, is published in the Journal of Environmental Management.

Ash

Processing a ton of sugarcane generates 280 kg of bagasse, which is widely burned as fuel, creating soot and ash. The bagasse is burned in blast furnaces with little or no environmental control, Faez noted. “The soot is supposed to be filtered away. The ash is useful because it contains carbonaceous matter, mainly carbon and silica. Moreover, its porosity facilitates adsorption. Several ash reuse projects are in progress, aiming above all to recover the ash and use it as an additive in ceramic material, bricks or asphalt. But this is the first time ash has been used unmodified to recover nutrients from vinasse,” she said.

The ash has a mixed composition, including particles with various structures ranging from spherical to tubular fibrous, prismatic, and irregular. The tubular fibrous particles have the most carbonaceous matter, while the angular irregular particles contain a large proportion of silica. “Besides significant porosity, these particles have negatively charged hydroxyl and carbonyl groups that interact with the positive charge in the ions we’re interested in [potassium and nitrogen]. So there are chemical interactions [absorption] as well as the physical interactions that arise from the porosity [adsorption],” Faez explained.

Many researchers are looking for ways to enhance the nutrient sorption capacity (adsorption and/or absorption) of sugarcane bagasse ash with surface modification of silica-rich particles, she added. “It’s possible to add other chemical groups there, but this extra work was undesirable. We aimed to focus on two raw residues and find out what could be done with them to generate two value-added products with the lowest possible energy expenditure. We therefore used ash after simply washing and drying it. We assumed that the less processing required, the easier it would be to persuade sugar and ethanol manufacturers to include this new stage in the production process,” she said.

Vinasse

Vinasse is a problem because a large amount of oxygen is required to break down the organic matter both chemically and biochemically (with the help of microorganisms). Owing to high levels of potassium (about 4,000 parts per million), as well as phosphorus and nitrogen, vinasse is widely used as fertilizer, either neat or diluted. “When applied directly to the soil, which is the typical method, it can lead to acidification and salinization of the soil,” Faez said.

The law requires vinasse to be treated before being used as fertilizer. In São Paulo, the largest producer of sugarcane in Brazil, agricultural use of vinasse is regulated by Technical Standard P 4.231, which was published in 2005 by CETESB, the state’s environmental agency.

“Many scientists are interested in vinasse and in finding out how to reduce its biochemical oxygen demand, but we know of no other research aimed at reusing its nutrients,” Faez said.

For her, vinasse is a continuation of the distillation process and contains many compounds that end up generating organic acids along the way. “So we’re undoubtedly also retrieving other components of vinasse during the sorption process,” she added.

The scientists were able not only to recover the desired nutrients but also to improve the vinasse itself. “We improved its acidity, by raising its pH to around 7, which is neutral, thanks to the alkalinity of the ash. In addition, we successfully demonstrated the potential of the ash as a biosorbent of nutrients that are efficacious for the treatment of vinasse,” Faez said.

They began by identifying the ideal conditions for sorption using a solution that mimicked vinasse. They placed the ash in the solution and left it on a stirring table. The result was 2.5 grams of ash after 6 hours of contact between the ash and the liquid.

After they had identified the ideal conditions of sorption, they performed two tests with unmodified vinasse. First, they blended 2.5 g of ash and 100 mL of vinasse under predetermined conditions for 6 hours and 24 hours. The second test was a three-stage procedure totaling 72 hours, with substitution of the ash in each stage.

“In the first case, we used the smallest possible amount of ash for the shortest possible time in order to measure the concentration of the ions of interest. We found that if we left the same ash in the vinasse for a long time, the process was inefficient. So we performed the second test, which lasted 72 hours, in batches, swapping out the ash every 24 hours,” Faez said.

The potassium- and nitrogen-rich ash that resulted from the procedure can be used as fertilizer, and the non-acidic vinasse will have a less negative impact on the soil. “Another student of mine is starting to evaluate the use of treated vinasse and to compare its effects on the soil with those of non-treated vinasse,” Faez said.

The idea of sustainability, she added, has given rise to a revolutionary process in which production cycles can no longer be open but must be closed without leaving footprints. “It’s historical. That’s how the history of chemistry has unfolded. Our main problem now is how to minimize the use of mineral resources. The fertilizers we use are obtained by mining. Also, excessive use of these compounds has an impact. We can’t afford any more losses, so there must be no more wasteful residues. Anyway, waste is inappropriate. Residues are opportunities, not problems,” she said.

The article “Unlocking agronutrient resources: Sorption strategies for sugar-energy industry waste” is at: www.sciencedirect.com/science/article/abs/pii/S0301479724006200?via%3Dihub.

Source: https://agencia.fapesp.br/53839